The spout pouch is a kind of flexible packaging. Spout pouches are used for packaging liquid and solid products. These bags are becoming more and more popular because they are economical and environmentally friendly. You can customize the spout pouch by printing on it to make it more attractive to customers.

1. Know the spout pouch material

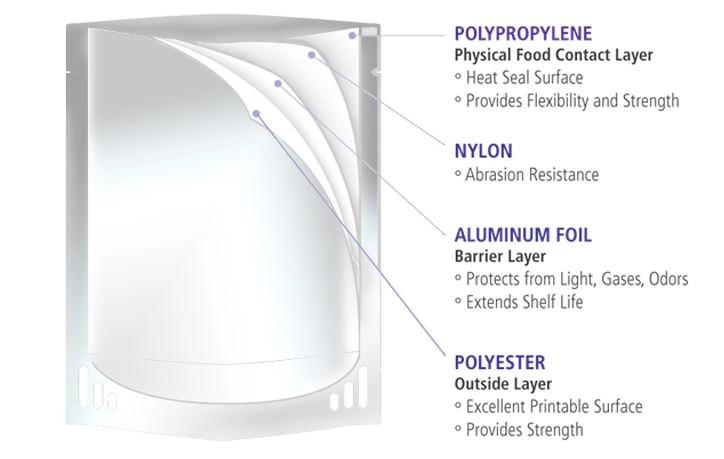

The product inside the spout pouch needs to be protected, so you should be very discerning in the choice of materials to use. The outer layer, inner layer, and middle layer of the spout pouch use different materials.

For the inner layer, use LDPE material and cast polypropylene. This is because the material can withstand high temperatures and is heat-sealable. The above properties allow the printed spout pouch to contain and retain heat.

For the middle layer, use aluminum foil. This is due to their high definition and stiffness. In addition, aluminum foil and nylon have high melting points. These properties make your ostomy bag resistant to moisture and oxygen.

The outer material of a spout pouch is made of oriented polypropylene and polyethylene terephthalate. Oriented polypropylene has a high degree of clarity, thus increasing the barrier properties of the spout pouch. Polyethylene terephthalate is both strong and temperature resistant.

This helps prevent damage to both contents and packaging. Additionally, it provides temperature resistance for printed spout pouches.

Here we discuss the various materials for making spout pouches and how they influence the printing technique.

2. Choose or Design the Artwork or Graphics to Print on the Spout Pouch

The choice of artwork for a printed spout pouch will depend on where you will be using it and your budget. Also, what’s inside the spout pouch will greatly determine your choice of artwork.

You also have to keep the target market of your product in mind, which enables you to make a good investment when designing your printed spout pouch. By doing this, you can customize and design your printed spout pouches to meet customers’ satisfaction.

Also, when designing your printed spout pouch, always make sure to customize it to make it unique from the competition. Always create and design spout pouches in different shapes and sizes, as this will easily grab the attention of your customers.

Always the design shall be a limit to what it can hold. Then considering the above factors enables you to consider important factors such as pouch shape, quality, and quantity of printed self-priming pouches and their contents. Choosing artwork for the spout pouch will depend on the printing technique you will use.

3. Choose the printing technology of the spout pouch

You can print on spout pouches using a variety of techniques.

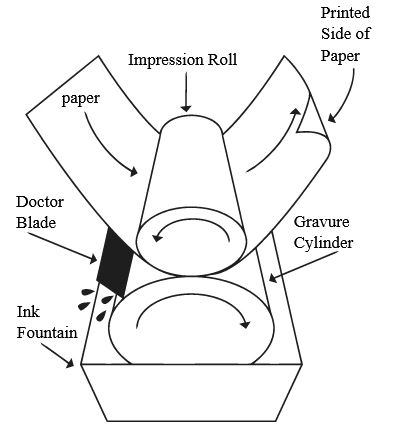

1) Gravure printing spout pouch

This technology is simply a long version, of high-quality, high-speed printing technology. Like engraving, this technique produces detailed and beautiful images on your spout pouch. The minimum run size for this printing technique is 10,000 bags. This technique will also give you nine different color printing options.

This technique produces high-quality, low-cost spout pouches. Here, the images, designs, and text to be printed are engraved on the surface of the metal sheet.

The special ink is then used to fill the engraved area. Finally, the printing plate is rotated on the cylinder, and the image and text are transferred to the spout pouch.

A) Advantages of gravure printing spout pouches

- It produces high-quality images.

- Its operating costs are low at high production volumes.

- Print cylinders withstand high-volume runs without loss of image quality.

- This method can be used to print films such as nylon in a wide range of thicknesses.

B) Limitations of gravure printing spout pouches

- It’s very expensive to start up, meaning you have to make thousands of copies to make a profit.

- The preparation time for the cylinder is very long, so special skills are required.

- Rotogravure printing has rasterized text and lines.

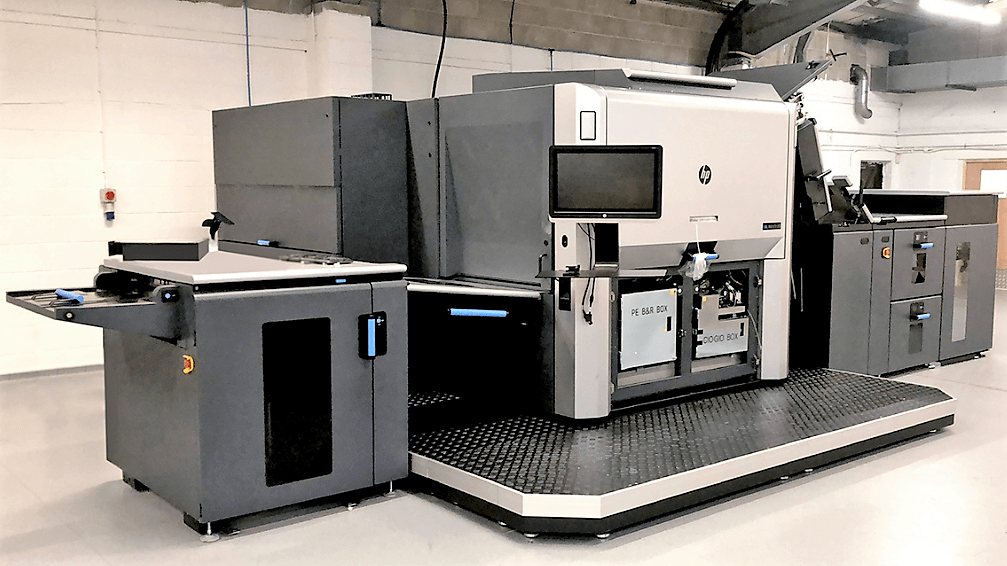

2) Digital printing spout pouch

You can use this printing technology to print complex text and images on a medium-quality surface. Here, using ink-based printing technology, branding, and graphic elements are applied directly to the self-priming bags.

There is no minimum run for this technique. The above statement just means that you can print 200 to 20000 sachets and it depends on your specifications. Digital printing technology produces expensive self-priming bags.

A) Advantages of digital printing spout pouches

The advantages of using digital printing on spout pouches are as follows:

One of the outstanding advantages of this technique is that there are no plates involved here. You will get very vibrant colors when using this technique.

This technology has the shortest setup time, which enables you to get the best value for short runs. Digital printing technology has the fastest turnaround time.

Thanks to this technology, many paper companies are producing a paper that can be used here. This allows you to choose the paper you want to use. The technology can add online completion to the workflow.

B) Limitations of digitally printed spout pouches

Digital printing of spout pouches has the following limitations:

As the prints get longer, the quality of the print on the spout pouch will degrade. You won’t be able to print on jetted pockets with metallic inks using this technique because the ink will short out the press. This is because the technology uses only CYMK inks. Also, you cannot use this printing technique to spout pouches for food.

This is because the ink used is not permitted under the Food and Drug Administration regulations that guide food packaging. Customized colors for your spout pouches are very difficult as printing techniques make better use of the CYMK color range.

They are expensive if you use a longer runtime. You can only use digital printing on certain papers, the range of papers used here is not extensive. Spout pouches printed using digital printing techniques tend to fade faster in direct sunlight than other printing techniques.

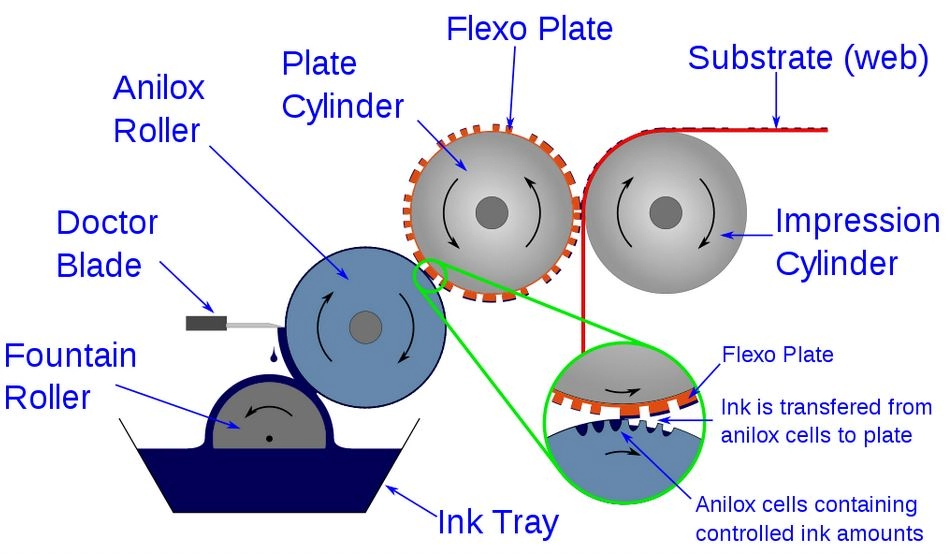

3) Flexographic printing spout pouch

Use this technique for simple surface printing. The technique uses sheets of flexible photopolymer that you wrap around a rotating cylinder to get each color.

The text of each color is then raised from the surface of the board. Only the raised areas of the plate surface are inked and therefore printed.

The technology is used to print simple text and images at a low cost. This printing technique is popular when printing large quantities of labels on spout pouches.

A) Advantages of flexographic printing spout pouches

Versatile: It means you can use it on any non-absorbent material. When you compare it to rotogravure, it is a very fast printing technique.

Compared to other printing technologies, flexographic printing technology supports a wide range of colors. In the printing of spray pockets, you can use flexographic printing technology with water-based inks and oil-based inks.

B) Limitations of flexo printing spout pouches

The technology is not advanced so it is not possible to create intricate and extensive artwork on your spout pouch. Compared with other printing techniques, the final color on the printed self-priming bags used by this technique is not bold.

If you want high-end images, flexo printing technology can’t meet your needs. The flexographic design process is less dynamic because it is old technology.

4. Benefits of printing bagged spouts

Printed spout pouches have several benefits, including:

1) Sustainability

This is because they take up less space and a lot of printed spout pouches are transported by car. When less space is transported, it equates to using less fuel. Carbon emissions are therefore lower when fuel consumption is lower.

2) Durability

Printed spout pouches are durable compared to other packaging styles. Therefore, you can guarantee that the packaging and the contents inside will not be damaged. It simply means that you will drastically reduce the number of customer complaints.

3) Brand promotion

Printed spout pouches make your branding stronger while being simpler, more efficient, and more productive. This is because they offer complete control when it comes to graphics compared to alternative packs.

Additionally, the printed spout pouches have an attractive shape that enables customers to recognize them. This makes them easy to ingrain in the minds of consumers.

4) Economic

Printed spout pouches cost less than alternative packaging. This makes them the most economical yet optimal packaging option.

5) Environmentally friendly

The plastic content of the printed spout pouches is significantly reduced. This means they are made from natural resources rather than hard plastic.

5. Conclusion

Therefore, printed self-priming bags are the best choice for flexible packaging. This is because they are cost-effective and do not allow compromise on content and packaging.

Thanks…It’s a lovely note. this is more helpful to understand more about spout pouch print. I love the information I have gathered here, thanks so much, and keep up the good work. It has helped me